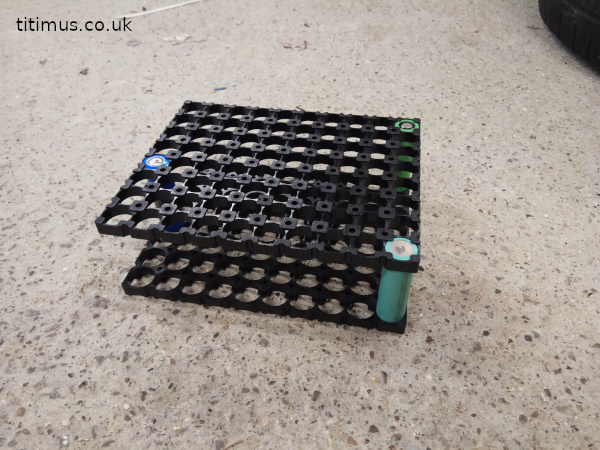

In order to improve and take full control of the battery on the Super Soco TC Max I'll try to build a new upgraded one. I think I can improve range around 25% by using 18650 cells. First thing to do is gather the parts and plan out how to arrange the 18650's. Some cell holders are obtained from AliExpress.

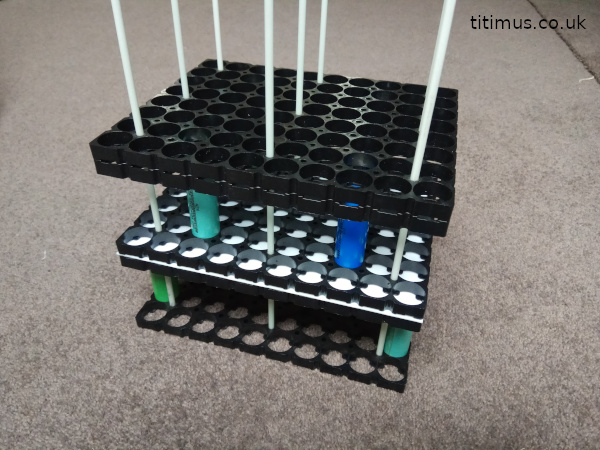

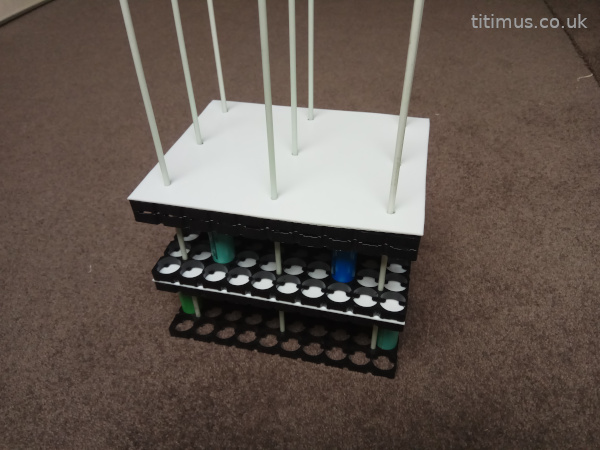

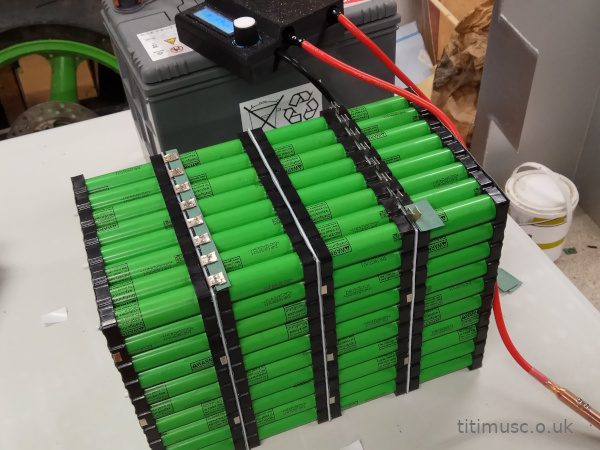

These cell holders are designed for 80 18650 cells. They will form a 16 parallel, 5 series module. There will be four modules stacked and connected in series making up a 16 parallel, 20 series battery pack with 320 cells total. I spent some time trying different cell holders in different arrangements. These ones cram the most cells in whilst maintaining an easy shape to work with. The holes between cells can accept a 4mm fibreglass rod to stop the modules moving around.

The new pack looks like it will be a good bit smaller than the original. Weight should also be considerably less. I've found some good quality 3500mAh cells which will make the entire pack 56Ah. A good upgrade from the original 45Ah battery.

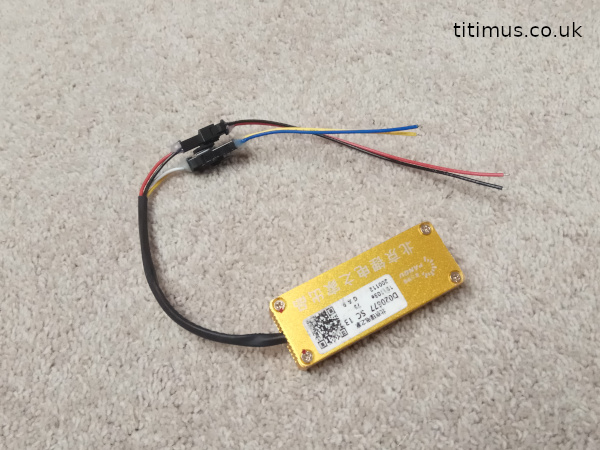

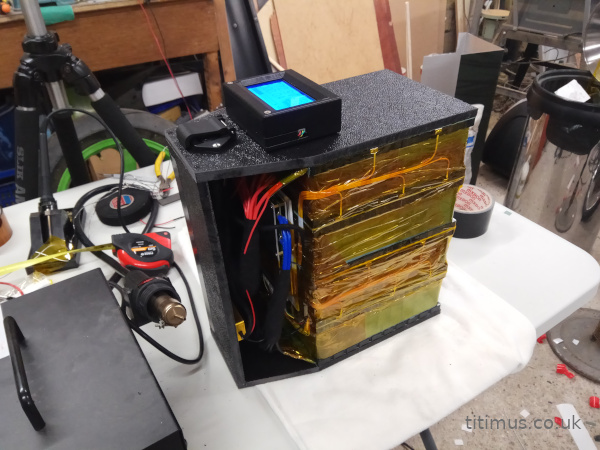

In order to maintain the cells within set parameters a BMS must be used. This Ant BMS seems to have plenty of cool features and spec including bluetooth programming and data acquisition. The temperature sensors are a bit big to fit between cells so I'll look for an alternative. The TC Max should pull around 70 Amps peak so the 100 Amp specification of this unit is fine.

This additional communication module should allow the bikes original battery meter to work.

Once the small holes in the cell holders are drilled clear with a 4mm drill bit, fibreglass rods can be inserted. These will help to maintain the structure of the battery and hold the PTFE separators in place.

1mm PTFE sheets are cut down to size and drilled to allow the fibreglass rods to pass through. PTFE has a high melting point so should remain intact even if high temperatures occur. It will insulate the modules from each other to prevent short circuit.

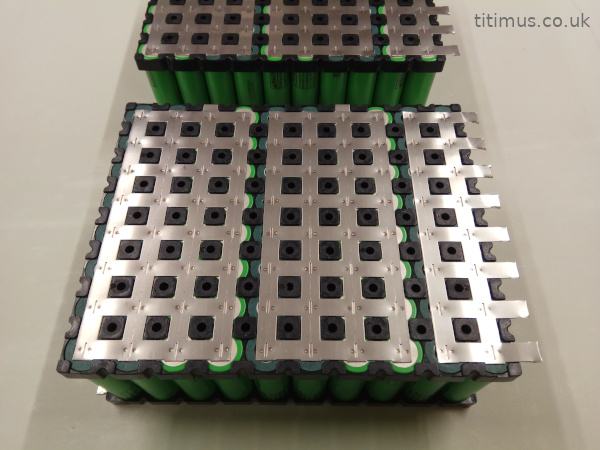

320 LG MJ1 cells are purchased and assembled into modules. The LG cells are rated at 3500mAh and maximum discharge current of 10A. The bike should pull just over 4A per cell so well within specification.

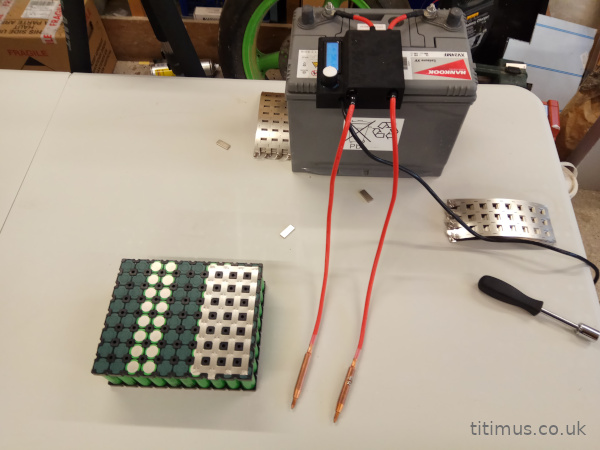

Two layers of 0.2mm pure nickel sheet are welded using a K-Weld welder. Extra tabs are left on the sides to allow the modules series connections and BMS cell connections.

These battery sockets are available online. They seem to be good quality and will allow the use of the original plug on the bike.

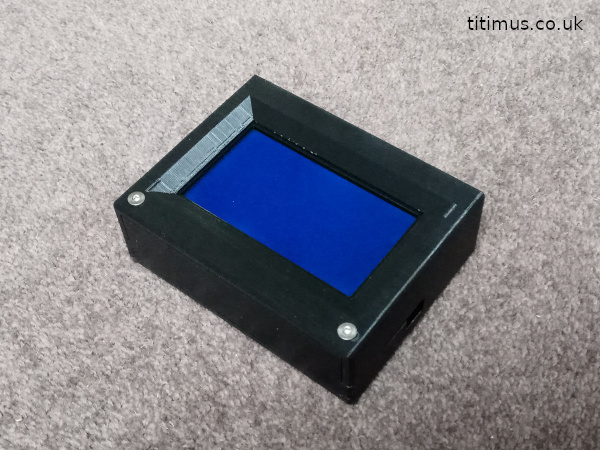

The BMS has built in bluetooth to allow programming and monitoring of cell voltages. To make it possible to check the pack and cell voltages without the use of a phone, a screen will be added to the battery. This unit should display total voltage, individual cell voltages and current both in and out of the battery. I believe it will also allow the BMS to be turned on and of or reset.

To be continued as I gather more parts...

Comments

Kind regards,

Pim

I'd probably fit a different BMS.

i've recently bought myself a tc Max and found your battery build vid on Youtube. Love your channel! i was wondering how is the battery holding up and how is the range now you've got probably a couple 100 miles on it?

for my daily commute i'm like 4 miles short in range so i have to charge on my work to get back home. so i would love to copy your battery build.

Thanks. The battery has done almost 5000 miles now. It seems to be holding up okay. I tested the capacity in August last year. I'll be doing it again this August to see how much degradation it's suffered. The range still seems good. It was expensive to build and isn't anywhere near as robust as the original battery so unless you really need it I wouldn't recommend building one. If I do a 40 mile round trip I still try to charge at my destination so I can ride more enthusiasticall y. If charging at your destination isn't too much hassle I'd keep doing that. At least until your original battery starts to degrade.

Few questions for you, from the POV of someone building and designing 600V packs at the 80kW+ level.

What methods of fusing are you using, if any? Do you have a Semiconductor fuse on the negative lead to prevent overcurrent, or between the segments?

Additionally, what rating is the material you're using between the segments, does it have an appropriate fire rating (UL Filing, typically UL94V-0 is standard IIRC). A good one to use is FR4, as that is rated to the UL94V0 standard, and you can just buy pieces pre-cut to size from PCBway by submitting a blank gerber file. We've had cells explode out both ends and the material just delams.

Neat project, good work!

On my battery only two pins other than positive and negative are connected in the socket. They connect to a module to send state of charge info to the display.

Can you contact me on private?

Thanks in advance!!

Nice battery. How is the temperature of the battery when in heavy use? I am worried about the plastic enclosure as it might have trouble removing heat from the cells.

Also, there is a problem when I try to use your links to Aliexpress. There is the following error: SEC_ERROR_REUSE D_ISSUER_AND_SE RIAL

Not sure about the links. They work for me.

This battery looks amazing, also the quality of work you put on in looks great.

Would you consider making one more for sale?

I'm getting my TC max soon, and would like a bigger battery, but unfortunately my electrical/elec tronics skills are close to 0.

Thanks,

Arpad

Thanks but sorry I can't make you one. The standard battery should give you good range.

Thanks for sharing this upgrade.

Planning to buy a TC max but the range for one way is just not sufficient for my commute (since i live uphill from my work). In your opinion, would it be possible to connect such a pack in parallel to increase range. The pack could be mounted in a saddle pack...

Cheers

Kai

Yes you could connect in parallel. You would need to make sure the voltage of each pack was the same before connection. I would say a pack about half the size of this pack might fit on the back.

1, the control board (I see it's offered for sale with the BMS) would it be the same one for CPX, or would I enquire better with the supplier ?

2, the control board is installed inside the battery case ?

3, is there a fuse also installed ?

thanks

I want to build the biggest energy battery pack that fits in the motorcycle´s battery pack compartment.

We begin by battery pack´s height. I think that it could consists in six modules stacked (six modules * 65 mm per module = 390 mm). I imagine that we would have to remothe the storage tray. Do you think that this is posible?

Six modules * 80 cells per module = 480 cells (3,6 V * 3,5 Ah = 12,6 Wh)

480 cells * 12,6 Wh per cell = 6,048 kWh

Thanks in advance

Thank you so much for the pictures and for your time.

At the fourth picture of your blog, we can see your four-modules battery pack next to the TC Max´s battery pack original case.

According to that picture, I think that we could add an additional module to your four-modules battery pack (in total five modules) and we would have a similar height to the TC Max´s battery pack original case.

The height of the TC Max´s battery pack original case is 321 mm. The height of five modules stacked is 325 mm (five modules * 65 mm per module = 325 mm).

We have a similar height in both cases.

Am I wrong about something?

Thanks in advance.

this project is really cool, congrat! I have a TC Max and I want to copy your battery pack :) Your youtube video contains almost every detail, I have two missing things: the alternative heat sensors and the battery case. can you give me some hints (maybe links ;) )

thanks!!!!

The heat sensors are standard thermistors. I used Vishay ones I got off ebay. Manufacturer code NTCLE300E3103SB . The top and bottom covers are made from 9mm polypropylene also purchased from ebay... https://www.ebay.co.uk/itm/361824620070?var=631087054490. The outer cover was 0.8mm polypropylene sheet... https://www.ebay.co.uk/itm/224642170534. If you're ordering the other parts from AliExpress please use my links. Thanks. Be careful. Good luck!