Before mp3s, wavs and flacs, before CDs and tapes, before radio and vinyl records, before any other type of audio recording or broadcasting... there was the Edison cylinder phonograph. For the first time in human history there was a device which enabled the recording and playback of sound.

In 1877 Thomas A Edison is credited with Inventing the phonograph, he went on to manufacture and market several models of cylinder phonograph including the subject of this article- the Gem. The Gem was the smallest and cheapest model available, this particular "B" model dates from around 1907 which makes it well over 100 years old! Cheap and portable the Gem made it possible for music to be taken out into the garden or on a picnic and was within affordable reach of an average person.

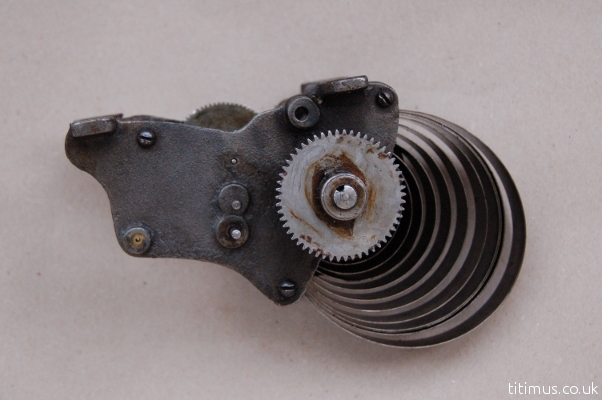

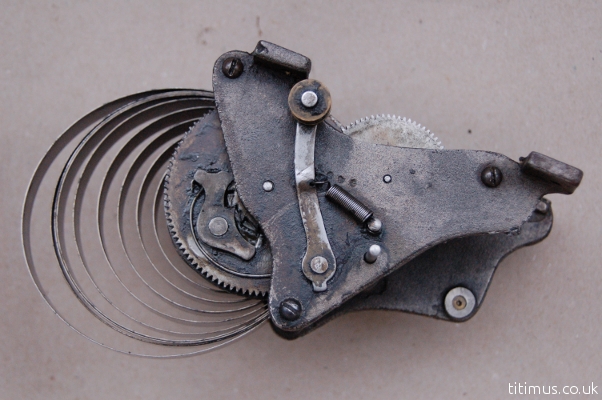

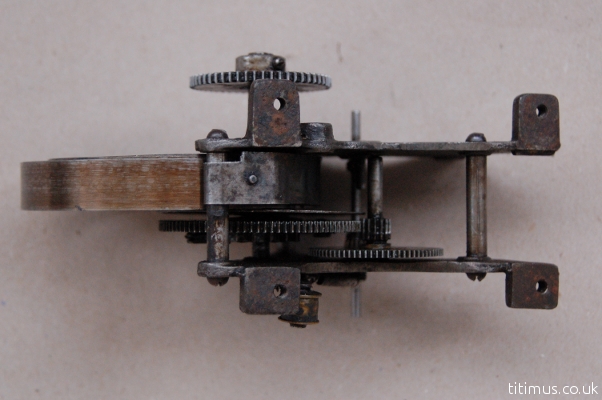

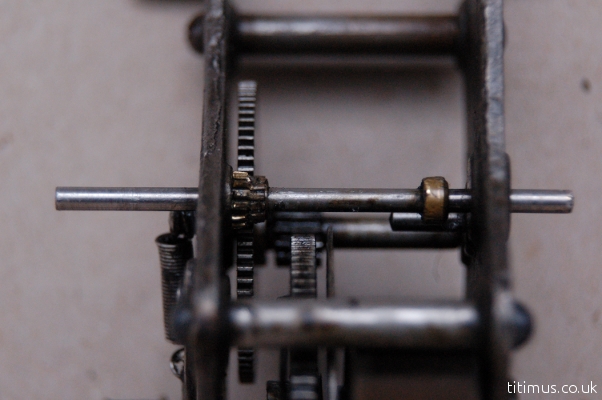

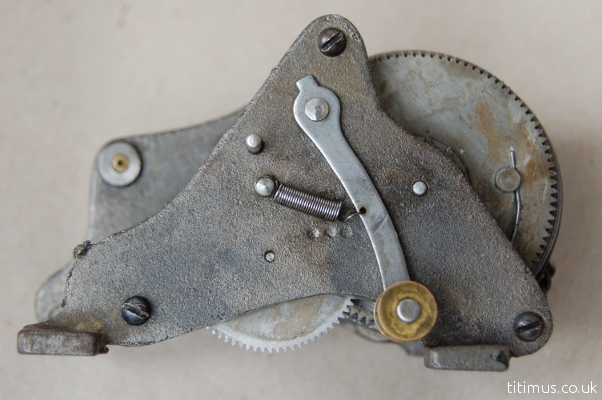

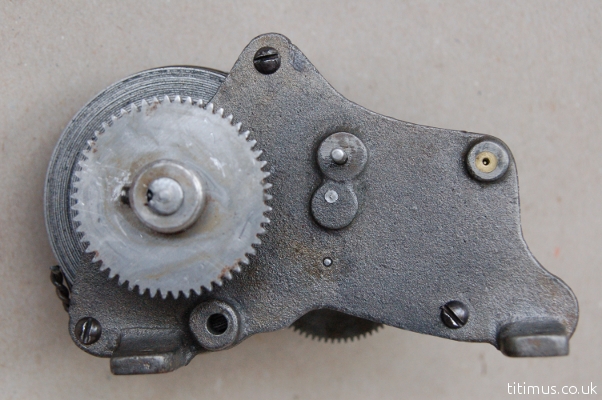

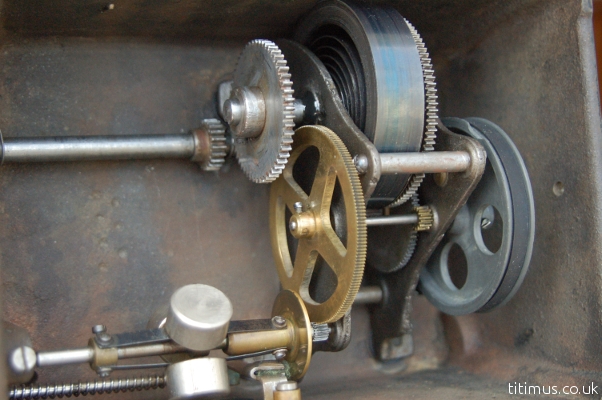

Although this Gem is still working it's not keeping a consistent speed. On inspection of the motor in operation the reason looks to be a bent output pulley shaft combined with a thick crust and sludge of old oil and grease. The pinion gear on the same shaft looks worn too and a bit mangled from a previous bodged repair. Judging by this and the damage on most of the screw heads this certainly isn't the first time this machines been apart. First job is to strip the heavy cast iron case of its motor and all parts for a proper clean, degrease and polish up. Some parts of the case have rust or paint worn off, rather than repainting it the original finish is just cleaned up. The wear and rust adds to the authentic well used and aged look. This old machine is so solidly built this project is more of a service than a restoration.

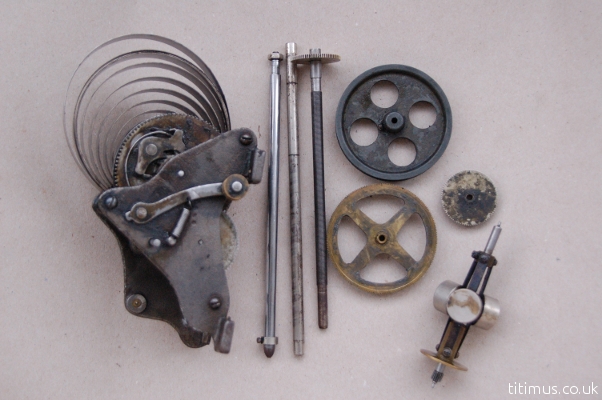

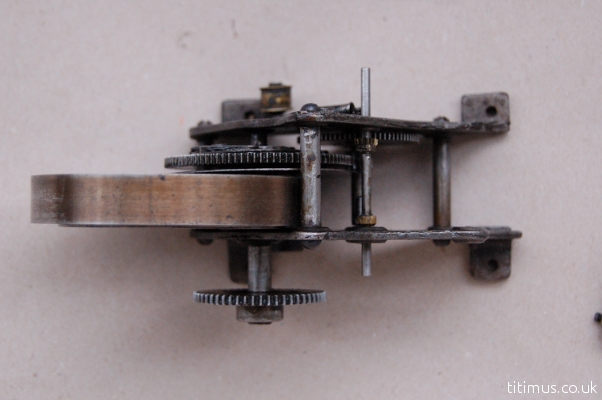

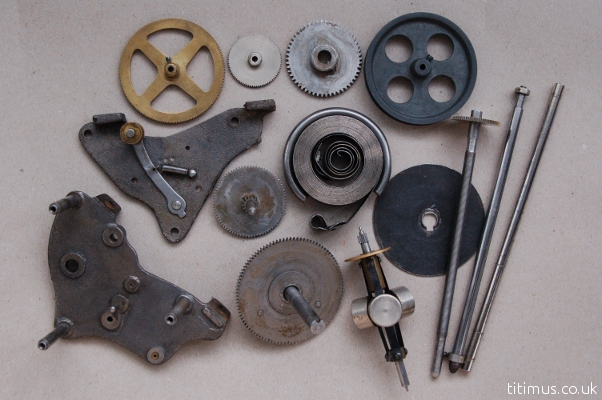

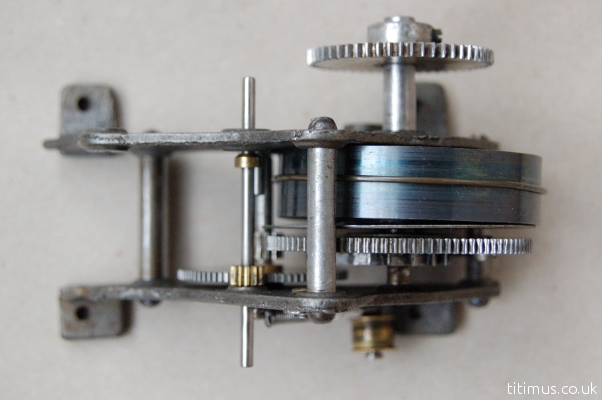

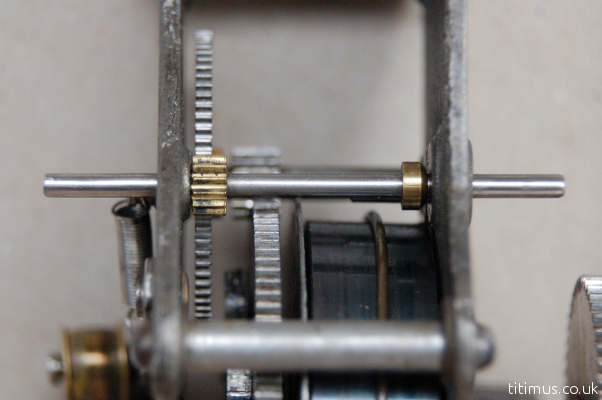

The motor and all other parts of the mechanism are absolutely covered in 100 years worth of gunk. Other than the bent output shaft all other parts look servicable. Once removed it's clear the speed governor shaft bearing pins have been bent from previous careless removal or refitting, these are very carefully bent back straight again and fortunately don't break. Both mandrel shaft and carriage rod look good but in need of a polish. The threads on the feed screw look perfect just in need of a clean and degrease.

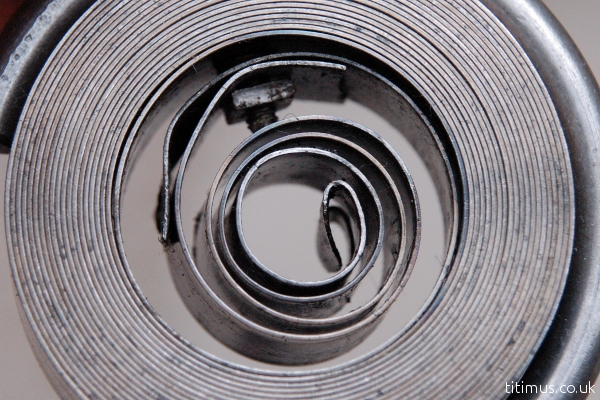

Once the motor side plates are unscrewed all the parts can be removed and cleaned. Taking the side plates off also reveals an old repair to the main spring. It had obviously snapped and in a "make do and mend" fashion been drilled and bolted back together. A new spring will have to be fitted to make a proper job.

After a few weeks of hunting down the new parts they finally arrive and the motor is reassembled with just a small ammount of oil on all the bearings. Cleaned, properly lubricated and with a new main spring this machine should work like new!

Once the motors back in the now clean case the crank and governor can be fitted. A few drops of oil are applied to the felt and the governor disc to allow smooth speed control.

With the internals all fitted and ready to go all the external parts are fitted. the shaft bearings have all been highly polished and lubricated to minimise friction. The model C reproducer is then droped into the carriage and we're ready for a test run!

All seems well, cylinders are playing at a nice constant speed and the mechanism is pretty quiet. The new mainspring easily plays two cylinders with power remaining. A new reproduction horn is sourced from the US and fitted to finish this little Gem off nicely.

This video of our Gem demonstrates how well it still works after over 100 years with just a minor service and repair. The cylinder is an original Edison gold moulded record of the Edison Concert Band playing the Grand March from Wagners Tanhauser.

Comments

Is it possible to get a replacement horn.

Thank you

Many thanks

Peter Hall